How AI & Automation are Changing Kitchens

The restaurant kitchen, long characterized by chaotic energy and manual processes, is undergoing a technological revolution. Artificial intelligence and automation are transforming back-of-house operations from artisanal craft to data-driven science, creating kitchens that are more efficient, consistent, and profitable. This shift goes beyond mere convenience—it's addressing fundamental industry challenges like labor shortages, food waste, and margin pressure while enabling new levels of culinary creativity and operational excellence.

From intelligent inventory systems that predict ordering needs to AI-powered cooking equipment that ensures perfect results every time, technology is enhancing rather than replacing human expertise. For forward-thinking restaurants, embracing these changes isn't about losing the soul of cooking; it's about augmenting culinary talent with tools that handle repetitive tasks, provide valuable insights, and create consistency at scale. The kitchens that will thrive in the coming years are those that successfully blend human creativity with restaurant automation tools and AI capabilities.

Intelligent Inventory and Supply Chain Management

AI is bringing unprecedented precision to one of the most challenging aspects of kitchen management: inventory control and ordering.

1. Predictive Ordering Systems

Modern systems analyze multiple data points to create remarkably accurate ordering forecasts.

- Demand Forecasting: AI algorithms analyze historical sales data, weather patterns, local events, and even social media trends to predict ingredient needs.

- Automated Purchasing: Systems automatically generate purchase orders when inventory reaches predetermined levels.

- Supplier Performance Analysis: AI tracks supplier reliability, quality consistency, and delivery timeliness to optimize vendor relationships.

- Price Optimization: Systems monitor market prices and suggest optimal ordering times to reduce costs.

2. Waste Reduction through Smart Tracking

Computer vision and AI are tackling the industry's massive food waste problem.

- Automated Waste Monitoring: Smart scales and cameras track food waste, identifying patterns and sources of excess.

- Recipe Yield Optimization: AI analyzes preparation processes to suggest adjustments that minimize waste while maintaining quality.

- Dynamic Menu Suggestions: Systems suggest menu specials based on ingredients approaching expiration.

- Portion Control Automation: Automated dispensers and measures ensure consistent portions, reducing waste and controlling costs.

AI-Enhanced Cooking and Food Preparation

The actual process of cooking is being transformed by intelligent equipment and systems.

1. Smart Cooking Equipment

A new generation of intelligent appliances is bringing consistency and precision to cooking processes.

- AI-Powered Ovens: Smart ovens use computer vision and sensors to adjust cooking time and temperature based on how food actually looks, not just timer settings.

- Automated Fry Stations: Intelligent fryers monitor oil quality, filter automatically, and maintain perfect temperatures for consistent results.

- Precision Grilling: Smart grills use thermal imaging to ensure perfect doneness across different cuts and thicknesses.

- Robotic Food Assembly: Automated systems assemble dishes with precision timing and portion control.

2. Computer Vision Quality Control

AI is being used to maintain consistent quality across all dishes.

- Plating Consistency: Cameras verify that each dish matches presentation standards before service.

- Ingredient Quality Assessment: Computer vision systems inspect incoming ingredients for quality and freshness.

- Safety Monitoring: AI monitors food handling processes to ensure safety protocols are followed.

- Allergen Control: Systems cross-check orders against ingredient databases to prevent allergen cross-contamination.

Intelligent Kitchen Management Systems

AI is creating kitchens that can essentially manage themselves, optimizing workflows and resources.

1. Automated Kitchen Display Systems

Modern KDS goes beyond simply displaying orders to actively managing kitchen workflow.

- Smart Order Prioritization: AI determines optimal cooking order based on preparation times, delivery schedules, and meal components.

- Station Load Balancing: Systems distribute orders evenly across stations to prevent bottlenecks.

- Predictive Timing: AI estimates completion times with high accuracy, improving coordination between kitchen and service staff.

- Integrated Recipe Guidance: Screens display recipe details, plating instructions, and allergen information for each dish.

2. Energy and Resource Optimization

AI is helping kitchens reduce their environmental impact while saving money.

- Smart Energy Management: Systems optimize equipment usage to reduce energy consumption during peak rate periods.

- Water Usage Monitoring: AI tracks and optimizes water usage throughout kitchen operations.

- Equipment Maintenance Prediction: Sensors detect early signs of equipment failure, allowing proactive maintenance.

- Carbon Footprint Tracking: Systems calculate and suggest ways to reduce the kitchen's environmental impact.

The Human-AI Collaboration in Modern Kitchens

The most successful implementations enhance rather than replace human staff.

1. Augmented Cooking Expertise

AI systems are becoming collaborative tools for culinary professionals.

- Recipe Development Assistance: AI suggests flavor pairings and recipe modifications based on culinary science and customer preference data.

- Technique Optimization: Systems provide real-time feedback on cooking techniques based on sensor data.

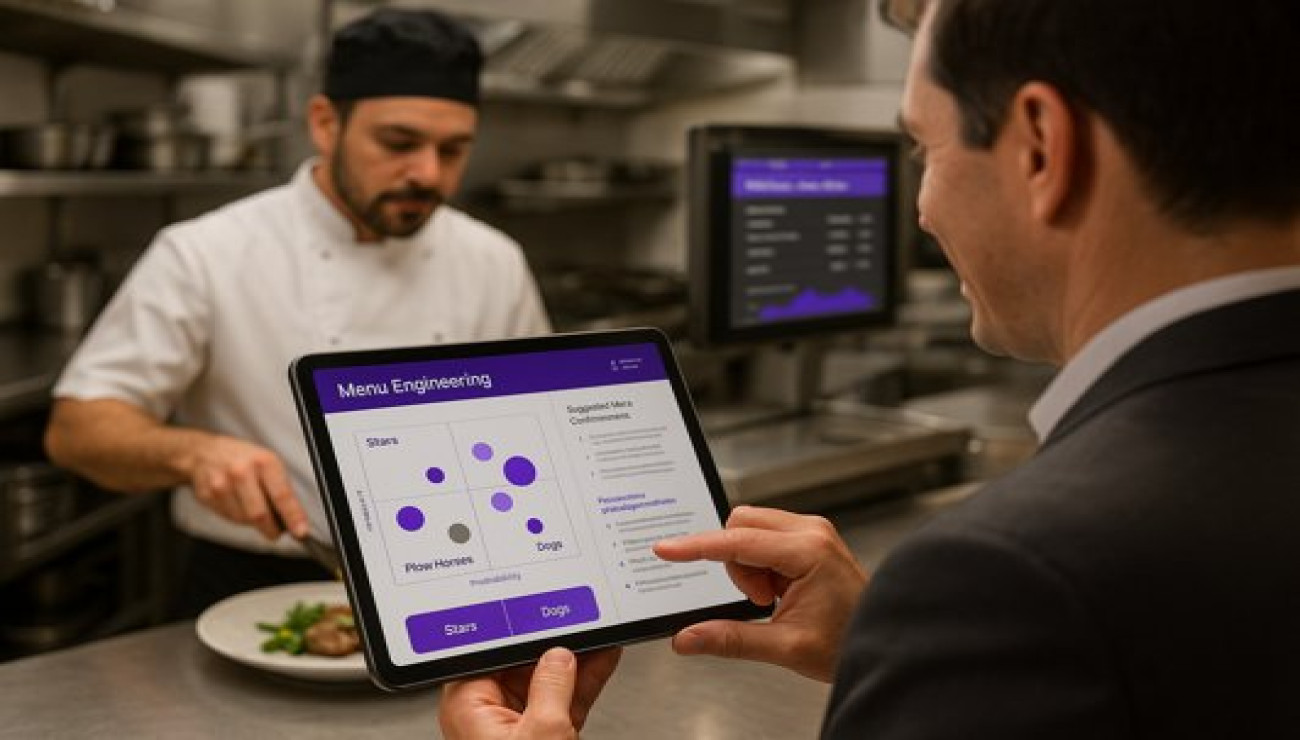

- Menu Engineering Support: AI analyzes sales data, ingredient costs, and preparation time to optimize menu profitability.

- Allergen-Friendly Adaptations: Systems suggest ingredient substitutions to accommodate dietary restrictions while maintaining flavor profiles.

2. Training and Skill Development

AI-powered systems are accelerating staff training and development.

- Personalized Training Modules: AI creates custom training programs based on individual staff performance and learning pace.

- Virtual Reality Training: Staff can practice techniques and procedures in simulated environments before working with actual ingredients.

- Real-Time Performance Feedback: Systems provide immediate feedback on technique, speed, and consistency.

- Knowledge Management: AI systems capture and organize institutional knowledge, making it accessible to all staff members.

A Case Study: From Manual to Automated

A multi-location restaurant group implemented an AI-powered kitchen management system across all locations. The system integrated inventory management, recipe costing, preparation tracking, and equipment monitoring. Each kitchen received smart cooking equipment that communicated with the central system, and staff were trained to work alongside the automated processes.

Results after six months:

- 34% reduction in food waste through better inventory management and portion control

- 28% decrease in energy costs due to optimized equipment usage

- 19% improvement in order consistency across all locations

- 42% reduction in training time for new kitchen staff

- 15% increase in kitchen throughput during peak hours

- Significant improvement in staff satisfaction as repetitive tasks were automated

AI Kitchen Implementation Checklist

- Assess Pain Points: Identify which kitchen processes would benefit most from automation.

- Start with Inventory: Implement AI-powered inventory management as a foundation.

- Select Interoperable Systems: Choose solutions that can integrate with each other and existing equipment.

- Phase Implementation: Roll out systems gradually to allow staff adaptation.

- Invest in Training: Ensure staff understand how to work with new systems effectively.

- Monitor and Adjust: Continuously track performance metrics and refine processes.

- Focus on Augmentation: Implement AI to enhance human skills, not replace them.

- Plan for Scalability: Choose solutions that can grow with your business.

The Future: Where AI Kitchen Technology is Heading

The transformation of commercial kitchens is just beginning, with several exciting developments on the horizon.

- Hyper-Personalized Nutrition: AI systems that create customized meals based on individual health data and preferences.

- Fully Autonomous Kitchens: Complete end-to-end automation from ingredient preparation to finished dish.

- Predictive Maintenance: AI that can predict equipment failures before they occur with increasing accuracy.

- Sustainable Operation Optimization: Systems that continuously optimize for minimal environmental impact.

- Integrated Supply Chain: Complete visibility and automation from farm to plate.

Conclusion: The Intelligent Kitchen Era

AI and automation are not removing the art and soul from cooking—they're removing the friction and inefficiency that prevent culinary professionals from doing their best work. The kitchens embracing these technologies are finding they can achieve new levels of consistency, efficiency, and creativity while addressing persistent industry challenges. The future belongs to kitchens that successfully blend human culinary artistry with artificial intelligence, creating dining experiences that are both technologically advanced and deeply human.

The most successful kitchens of tomorrow will be those where chefs and AI work together to create extraordinary experiences.

Comments (0)